Diamonds

Diamond Cutting

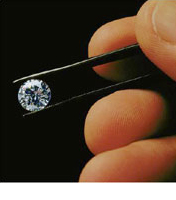

Diamond cutting and polishing

In its rough form, a diamond is a lackluster, translucent crystal. Transforming a rough diamond into a

sparkling jewel requires several procedures: cleaving, sawing, bruting, cross working and brillianteering.

Cleaving

Cleaving involves the removal of impurities or irregularities in the rough diamond. Using a second diamond

or a laser, a groove is carved into the diamond along a plane of weakness. A steel blade is placed in the

groove and a sharp blow is delivered which splits the stone. Cleaving requires particular skill; if pressure

is applied to the wrong area or in the wrong direction, the diamond may shatter. Not all rough diamonds

require cleaving or sawing - some diamond rough is well formed and is in ready-to-cut form.

Sawing

Diamond sawing is a twentieth century innovation. Although cleaving may be efficient, it limits the cutter

to shaping the stone according to its natural lines of cleavage. Sometimes, diamonds have to be cut against

a cleavage plane (against the grain). The diamond saw, a lubricated circular steel blade allows cutters to

go against the grain of the diamond without shattering it.

Moreover, the diamond saw allows diamonds to be salvaged from misshaped diamond rough. Sawing is a more

expensive process than cleaving, as it requires about one-tenth of a carat of diamond dust (applied to the

saw with oil) for every carat of sawed diamond. It is also a much slower process than the single-stroke

process of cleaving. It may take days to saw through a two-carat diamond. Extant methods include the use

of lasers to saw through diamonds.

Bruting

The diamond is placed in a lathe with another diamond that is rubbed against it to create the rough

finish of the girdle.

Diamond Polishing

Diamond polishing consists of two phases, crossworking and brillianteering. To give the diamond its finished

look, it is clamped to on an armature above a rotating polishing wheel (scaif). Diamond dust on the wheel's

surface grinds the diamond down to the desired angle. The scaif makes it possible to symmetrically polish all

the facets of the diamond at angles that reflect the most light.

Cross Working

Cross-workers carefully evaluate the clarity of the finished diamond in relation to its final size in

order to obtain the maximum value for the finished stone. The work is performed on a spinning polishing

disc covered with diamond powder. The diamond is held in a clamp and the facets are created one at a time.

Crossworkers polish 18 facets to stringent measurements and angles.

Brillianteering

The function of brillianteers is to create and polish the additional 40 facets to produce a brilliant

cut diamond with 58 facets.