Additional Information

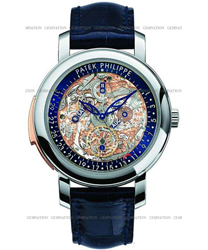

With its Reference 5104, Patek Philippe has created a prestigious timepiece that perhaps more than any other reflects the six underlying values of the last family-owned watchmaking company in Geneva: innovation and tradition, aesthetics and technology, complexity and simplicity. For the first time, a Grande Complication wristwatch crafted by Patek Philippe affords more than a caseback view of the mechanical marvels inside. The 5104 features a transparent dial that reveals the normally concealed complex mechanisms on the front. This is a feat that, yet again, required considerably more ingenuity than meets the eye.

The Ref. 5104 is unlike any other Patek Philippe wristwatch. It is the first Grande Complication with a totally transparent dial to showcase a number of elaborately crafted sub-mechanisms which ordinarily perform their tasks unseen: the perpetual calendar, the retrograde date, the minute repeater, the moon-age indication, and, of course, the wheel trains for the hours, minutes and seconds. A glance at these juxtaposed and superposed wheels, levers, springs, discs and hands readily reveals not only the intricacy but also the aesthetic beauty of these mechanisms. A number of very challenging problems had to be solved to afford this unprecedented view.

One of the greatest challenges was to legibly present on the transparent sapphire-crystal dial the four displays—the perpetual calendar, the subsidiary moon-age indication, and the hours and minutes—without obstructing the visibility of the fascinating mechanisms underneath. The solution was to make the subdials transparent. A retrograde hand moves along an arc on the periphery of the dial to indicate the date. The hour and minute hands are skeletonized. The days, months and current year in the leap-year cycle are imprinted on three circular zones of the transparent sapphire-crystal dial. Immediately beneath these zones, sapphire-crystal wafers rotate at their specific pace and position. Each of these wafers features a black rectangle providing the necessary contrast so that the day, month and year indications are clearly legible.

This clever solution created a totally new problem. How could these thin and delicate sapphire-crystal rounds be mounted on tiny steel arbors to assure perfect and durable positioning accuracy? Steel and sapphire crystal are very dissimilar materials. Sapphire crystal is brittle and cannot be press-fit on an arbor like a brass wheel. Any attempt to do this would cause the crystal to fracture into countless shards. Consequently, Patek Philippe had to develop a new manufacturing process especially for these transparent displays.

Sapphire crystal with steel – patent applied for by Patek PhilippePreparation: In a first step, a central hole is drilled through the sapphire-crystal discs that are only 0.2 millimeters thick. The hole is slightly larger than the diameter of the pinion on which it is to be mounted. Because the smooth surface of the crystal hardly builds up enough friction for a mechanical connection, a small circular zone around the borehole must be roughened and metallized with a vacuum deposition process. Now, the sapphire-crystal disc has a bondable zone that can be coated with tin. The tin coating is drilled through the middle and shaped into a bushing that must be somewhat smaller than the pinion arbor. With that, the sapphire-crystal disc is ready to be press-fit on the pinion and aligned with the pinion leaves.

Alignment: When fitting the pinion into the sapphire-crystal disc, the watchmaker must align the disc with the leaves of the pinion as accurately as possible so that the black contrast rectangle is correctly positioned beneath the white day, month and year indications. Because of the danger of fracturing, the latitude for corrections is very limited.

Brazing: As the final step, the pinion with the aligned sapphire-crystal disc is heated in a furnace to 240°C. At this temperature, the tin bushing is brazed to the pinion arbor. After slow and careful cooling, the parts are now concentric and firmly connected at just the right angle.

A moving view: both sides of a complicated movementThe acclaimed self-winding Patek Philippe caliber R 27 PS QR movement with a minute repeater, small seconds, and moon-age display at 6 o'clock, as well as a perpetual calendar and a retrograde date display, lies at the heart of this transparent masterpiece. For this new prestige version, it has been modified with decorative elements and design changes. The plate for the additional mechanisms is plated with red gold 5N. The mini rotor in 22K red gold 5N is recessed in the plate and features a floral pattern with inside surfaces hammered to a flat gloss and then rhodiumed. The Calatrava-cross cover of the centrifugal governor and the lateral slide for the minute repeater are crafted in red gold as well. Of course, the movement is hallmarked with the Geneva Seal as an official certification of the ultimate in craftsmanship. Finally, the view of the dial side of the movement shows all of the details that must be observed to comply with the criteria behind this rare and coveted seal of quality. All steel parts have straight-grained, carefully beveled flanks. The edges are chamfered at 45° and polished. Even on linear components, this is not a trivial operation and only the most experienced specialists can perform it on complicated parts with hard-to-reach interior angles. Another special feature of this caliber is that the calendar wheel train bridge and the large lever are skeletonized to reveal more details. It takes two entire days for an experienced craftsman to skeletonize these two parts alone. Another uniquely decorative element is the gold wheel for the moon-age display. With its curved spokes, it has the same shape as the third wheel in the manufacture’s famous tourbillon watches. Aficionados will notice that the retrograde date indication is inverted and now sweeps a 270° arc along the bottom half of the dial.

A case as complex as its inner lifeAt Patek Philippe, the art of complications is not restricted to the intricate inner workings of its timepieces. The degrees of difficulty involved in crafting the case of the Ref. 5104 are impressive as well. It picks up on the floral theme of the skeletonized hands and the rotor decoration. The flanks of the platinum case are embellished with red gold 5N intarsia work and even the lugs exhibit delicate red gold inlays. It takes infinite patience and countless hours of work to create the recesses in the hard platinum case in which solid red-gold form pieces are inserted. Even the smallest slip of the burin would ruin the case and render the work done useless. Thus, each case takes shape with the same passion and commitment lavished on the movement. To emphasize the transparence of this exclusive timepiece, the case features a display back with a sapphire-crystal inset to present, as in a show window, the magnificent caliber with its warm red-gold accents, carefully applied striping and perlage, the large Patek Philippe Gyromax balance, and the small beveled hammers and the gongs of the minute repeater. The exceptional watch is worn on a blue, large-scaled alligator strap secured with a 950 platinum prong buckle.

Patek Philippe’s Ref. 5104 Grande Complication pulls out all the stops and challenges to the limit the capabilities of the manufacture’s talented designers, watchmakers and casemakers. It takes two years just to craft the parts, assemble the movement, and adjust its rate to perfection. For this reason, the workshops can only complete eight to 10 of these intrinsically rare timepieces per year.